|

A brief description of the processes and

turn around times available to manufacture your

identification products.

|

|

GROUP 1

|

GROUP2

|

GROUP 3

|

|

Etching

|

|

|

Etching is a process by which a chemical is used to remove (etch) unmasked areas on metal sheet stock. Etched areas may be filled with colored paints. Also known as photo etching and chemical etching. Etched nameplates offer excellent abrasion resistance and are still legible without paint fill or after being painted over due to their recessed areas. |

|

Process used to produce: |

Nameplates, Tags,

Legend Plates, Overlays, and

Signs |

|

Material(s): |

Stainless Steel,

Aluminum, and

Brass |

|

Typical lead-time: |

10-15 days |

|

Most economical

quantity: |

low to high volume ( 1+ identical pieces) |

|

Photo Anodizing

|

|

|

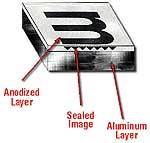

Photo Anodizing is a process by which a partially anodized, photosensitized, aluminum alloy sheet is exposed and developed (similar to photographic film) to produce a black and silver image. The aluminum may also be

dyed to produce multi-color images. The final step is to complete the anodizing process by sealing the aluminum to protect all of the images beneath the aluminum’s anodic layer. Photo Anodized nameplates are some of the most durable nameplates available, with approvals for many military, space, government, and industry applications. Also known as Metalphoto and Photo-Metal. |

|

Process used to produce: |

Nameplates, Legend Plates,

Tags, Overlays, and

Signs |

|

Material(s): |

Photosensitive

Aluminum |

|

Typical lead-time: |

4-15 days |

|

Most economical

quantity: |

low to medium volume ( 1 to 1000 identical pieces) |

|

Digital Printing

|

|

|

The Digital Printing process uses heat and pressure to fuse colored resins to a material. Also known as thermal transfer printing. This is the best process for short-run and fast printing on films (thin plastics) offers good durability. Additional protection from UV, chemicals, and/or abrasion can be obtained with

overlamination. |

|

Process used to produce: |

Decals, Overlays, Signs,

Legend Plates, and Nameplates |

|

Material(s): |

Vinyl,

Polycarbonate Film,

Polyester |

|

Typical lead-time: |

2-7 days |

|

Most economical

quantity: |

low to medium ( 1 - 1000 identical pieces) |

|

Screen Printing

|

|

|

In the Screen Printing process, a squeegee is used to force ink through a selectively masked fabric screen that is used as a stencil. Screen Printing provides the most vivid, color-fast image of all printing types and offers good durability. Additional protection from UV, chemicals, and/or abrasion can be obtained with

overlamination. Also known as silk screening. |

|

Process used to produce: |

Nameplates, Decals,

Overlays, and

Signs |

|

Material(s): |

Vinyl,

Polycarbonate Film,

Polyester,

Aluminum,

Brass,

Stainless Steel, and others |

|

Typical lead-time: |

typically 10-15 days |

|

Most economical

quantity: |

medium to high volume ( 250+ identical pieces) |

|

Flexographic Printing

|

|

|

Flexographic Printing is a roll to roll (or web) process which uses flexible, photo polymer, raised-image printing plates wrapped around cylinders to transfer fast drying inks to a substrate. Also known as Flexography or Flexo printing. |

|

Process used to produce: |

Roll Labels |

|

Material(s): |

Paper |

|

Typical lead-time: |

10-15 days |

|

Most economical

quantity: |

medium to high volume ( 250+ identical pieces) |

To Top of Page << previous

more >>

The information contained on this

page and on this web site is intended to give our customers a

better understanding of The Cutting Edge’s products and

services, and is for general use only. Specific questions

regarding applications, specifications, and capabilities of The

Cutting Edge should be directed to our customer service

department. No warranties are expressed or implied. |