|

A brief description of the processes and

turn around times available to manufacture your

identification products.

|

|

GROUP 1

|

GROUP 2

|

GROUP 3

|

|

Engraving

|

|

|

Process, by which a computer controlled, rotating cutting tool is used to machine (remove material from) plastics and metals to produce text and images. (see specific types of engraving below) |

|

Process used to produce: |

Legend Plates,

Nameplates, Overlays, Signs, and

Tags |

|

Material(s): |

2-ply and 3-ply Front and

Reverse Engravable Plastics,

Acrylic,

Polycarbonate Sheet (Lexan),

Phenolic,

Teflon,

High Pressure Laminate (Formica),

Aluminum,

Brass,

Stainless Steel,

Zinc, and others |

|

Typical lead-time: |

2-7 days |

|

Most economical quantity: |

low volume ( 1 - 100 identical pieces) |

|

Front Engraving

|

|

|

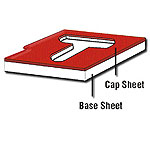

Front engravable plastics are composed of two layers of plastic laminated together. The top layer or "cap sheet" is typically a contrasting color to the bottom layer or "base sheet".

Front engraving is a method by which an image is engraved from the front, or through the cap sheet to reveal the base sheet. The cap sheet color is the products background color, and the base sheet color is the engraved text or image color. Front Engraved nameplates offer good abrasion resistance and in many cases are still legible after being painted over due to their recessed areas. |

|

Process used to produce: |

Legend Plates,

Nameplates, Overlays, Signs and

Tags |

|

Material(s): |

2-ply and 3-ply Front

Engravable Plastics, Acrylic,

Polycarbonate Sheet (Lexan),

Phenolic,

Teflon,

High Pressure Laminate (Formica),

Aluminum,

Brass, Stainless Steel,

Zinc, and others |

|

Typical lead-time: |

2-4 days |

|

Most economical quantity: |

low volume ( 1 - 100 identical pieces) |

|

Reverse Engraving

|

|

|

Reverse engravable plastics are composed of two layers of

a modified acrylic laminated together. The top layer or "cap

sheet" is clear. The bottom layer or "base sheet" is

colored and opaque.

Reverse engraving is a method by which the image to be

engraved is reversed and engraved from the back side, or through the base

sheet. The engraved text or image is then filled, or colored, with paint(s).

Benefits of this process include: Multi-colored graphics are protected

beneath a protective clear acrylic surface, smooth easy to clean surface

and

no recessed (or front engraved images) to fill with dirt and dust. |

|

Process

used to produce: |

Legend Plates, Nameplates,

Overlays, Signs and

Tags |

|

Material(s): |

2-ply and 3-ply Reverse

Engravable Plastics, Acrylic,

Polycarbonate Sheet (Lexan) |

|

Typical

lead-time: |

2-7 days |

|

Most

economical quantity: |

low volume ( 1 - 100 identical pieces) |

|

Burnishing

|

|

|

Type of engraving using a rotating diamond tipped tool to remove the protective finish on aluminum and brass. These engraved (or burnished) areas are then chemically oxidized or electro-chemically etched to produce black text or images. |

|

Process used to produce: |

Legend Plates,

Nameplates, Overlays and

Tags |

|

Material(s): |

Aluminum,

Brass,

Zinc, and Glass |

|

Typical lead-time: |

2-4 days |

|

Most economical quantity: |

low volume ( 1 - 100 identical pieces) |

|

Diamond Drag Engraving

|

|

|

Type of engraving using a non-rotating diamond tipped tool to mark metal materials. Text or images on finished products are similar in appearance to stamped text. |

|

Process used to produce: |

Legend Plates,

Nameplates and Tags |

|

Material(s): |

Stainless Steel,

Aluminum, and

Brass |

|

Typical lead-time: |

2-4 days |

|

Most economical

quantity: |

low volume ( 1 - 100 identical pieces) |

To Top of Page

more >>

The information contained on this

page and on this web site is intended to give our customers a

better understanding of The Cutting Edge’s products and

services, and is for general use only. Specific questions

regarding applications, specifications, and capabilities of The

Cutting Edge should be directed to our customer service

department. No warranties are expressed or implied. |